Steel strapping is a major safety hazard and more expensive

Steel strapping is a major safety hazard and most expensive strapping per foot.

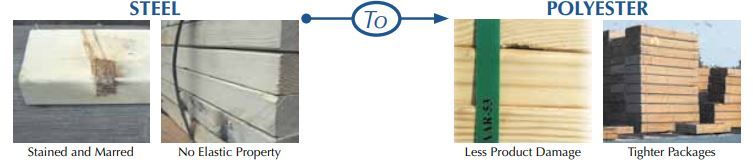

Steel strapping is an older solution that presents a serious safety hazard throughout its life cycle. It is one of the leading causes of accidents in employees and customers cutting their arms or legs on protruding or discarded steel strapping. Furthermore, the cost of steel continues to be on the rise and manufacturers raise steel strap pricing across the board. Per foot, steel strapping is the most expensive strapping.

Polyester strapping is safer and more cost-effective

First and foremost, polyester strapping greatly reduces the risk of injuries, lost time and the liability caused by the weight and sharp edges and ends of steel strapping. Polyester is 4-times lighter, making it much safer and easier to handle.

Switching to polyester strapping means fantastic cost-savings for your packaging operations. On average, you can save 30 to 40% on strapping when you replace steel strapping with polyester strapping. In addition to that polyester strapping can be used without metal seals, delivering additional savings.

Polyester strapping improves productivity

Longer coils of polyester strapping require less change time and improve productivity. Furthermore, replacing a manual strapping tool with a battery-operated or pneumatic strapping tool will help get those pallets ready for shipping even faster.

Polyester strapping protects products better, reduces environmental impact

Polyester strapping has higher impact resistance and ‘elastic memory’. Therefore, it holds packages tighter, provides better load retention and reduces the risk of product damage in shipping. Polyester strapping is cleaner and non-corrosive, so it will not rust or stain products. In addition to that, polyester is non-abrasive and will not mar products. Plus, polyester strapping from Polychem is made from 100% recycled materials (giving plastic bottles a whole new life) and is recyclable, where facilities exist.

Polyester strapping is safer, less expensive and holds loads tighter, reducing the risk of product damage in shipping.

Tips for safer strapping

- Always place a minimum of 2 straps in the load direction (which is how the pallet is placed on a truck, oriented front to back).

- With 2 and more layers of cartons on a pallet, use 4-way strapping method.

- Always use the right tool and the right seal for a particular strap.

- Ensure the maximum strength of the strapping tool is 15-20% higher than the break strength required for your load. PACKPRO packaging specialists can help you calculate that!

- Feed the strap under the pallet easier and faster with a pallet threader.

- Never use strapping as a handle.

- If not used correctly, strapping can present a safety hazard. Ensure your team follows all safety precautions when using strapping.

Putting it all together

By replacing steel strapping with polyester strapping, you choose a superior performing product that can help you save up to 40% on average and create a safer and more productive work environment.