Packaging Equipment

High-performing packaging equipment maximizes packaging productivity and efficiency, giving you a competitive edge. Packaging line automation improves your flexibility to handle more product varieties and packaging sizes. Plus, it helps meet the needs of an evolving workforce.

Selecting the right packaging equipment is key to increased packaging productivity and consistency, better protected products and reduced environmental impact. Let PACKPRO packaging automation experts help you maximize the performance of your packaging operations by selecting the machines that best suit your objectives and matching them with the optimal materials.

Ensure increased productivity of your packaging operations by choosing the right packaging equipment.

Request a FREE packaging equipment consultation today.

Choosing the Right Equipment for Your Packaging Operations

When it comes to packaging automation, you can rely on PACKPRO experts to help you make the right choice. Furthermore, you have peace of mine knowing that PACKPRO Engineering Technicians will look after any regular maintenance or emergency repairs. With nearly 20 years of experience, we’ve helped many companies in various industries and look forward to helping you!

- E-commerce and Omni-Channel Fulfillment

- Industrial Manufacturing and Distribution

- Protein and Produce Processing

- Medical and Healthcare Supply

- Food Packaging

- Ready Meal Kits

When working with PACKPRO, you have access to the leading equipment manufacturers, whether for end-of-line packaging equipment, bagging machines or food packaging equipment. In addition, our experienced packaging automation advisors help you assess equipment options and make informed decisions about the packaging equipment that will best suit your operations.

END-OF-LINE PACKAGING EQUIPMENT

End-of-line packaging refers to the stage in which the final packaging is placed on a finished product before it proceeds to the shipping and distribution stages. It may consist of a variety of operations, including bagging, boxing, void filling, sealing, shrink-wrapping or stretch-wrapping, and palletizing.

Boost the productivity of your end-of-line packaging operations with the following equipment.

CASE ERECTORS AND CASE SEALERS

Case erectors and sealers are used to form a secure and sealed transport container for the products. Case erectors form the cases from pre-cut flattened cardboard, while case sealers apply adhesive to ensure the assembled case maintains its form during transport. Both types of packaging equipment are available in semi-automatic or fully automatic variations and are suitable for use with corrugated boxes, cases, and trays.

VOID FILL MACHINES

Void fill machines offer quick feed, increasing the speed of inserting packing material, such as bubble wrap or paper, into empty areas within boxes and other shipping containers. The packaging material reduces the movement of the product during the transportation, minimizing the risk of damage and ensuring the product will be delivered in as-made condition. The void fill systems we offer are built to handle a variety of materials, including eco-friendly recyclable and compostable packing products. See how they work.

TAPE DISPENSERS

Switching from pressure-sensitive tapes to water-activated tapes, dispensed by a machine is reported to improve your case sealing productivity by 21% on average. WAT dispensers are available in both manual and electric forms and accommodate a variety of tamper-evident, reinforced printable tapes.

STRETCH WRAPPERS

Stretch wrappers enclose products or pallets of products in plastic stretch film to contain and protect the products during transport. They have proved to improve consistency of containment, productivity and reliability of wrapping operations, while reducing film in use. Whether it is semi-automatic, fully-automatic or self-propelled wrappers; turntables, rotary arms, rotating rings or horizontal rings, we will guide you along the way so that the wrapping equipment you choose meets your current and future requirements.

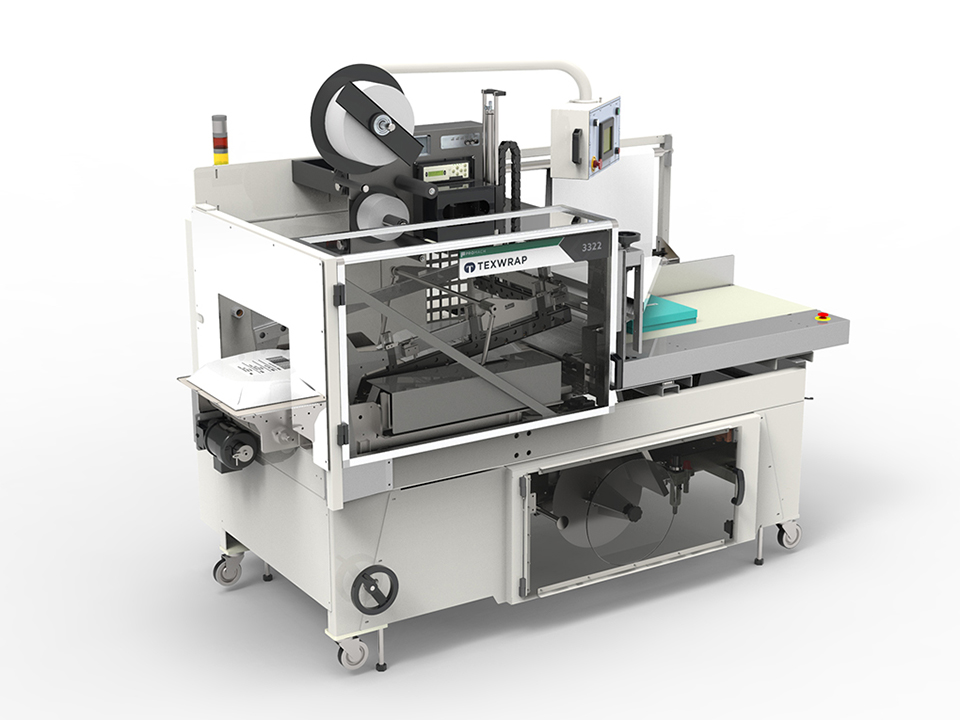

SHRINK WRAPPERS AND SHRINK BUNDLERS

Whether you are wrapping for retail display, bundling, multi-packing, using supported product or unsupported product, we have you covered with standard and custom shrink wrappers, infeeds, and tunnels. Produce “bull’s eye” multipacks consistently, with reliable seal, for superior product containment. Reduce packaging costs as well as drayage costs with shrink bundlers by eliminating the need for cartons, trays or cases.

PALLETIZERS

Palletizers are automated machines that place completed boxes of products onto pallets in preparation for shipping. Depending on your requirements, we can help select between low-infeed or high-infeed conventional palletizers as well as robotic palletizers.

BAG PACKAGING EQUIPMENT

Increase packing efficiency and reduce shipping costs with bagging machines. They automate the process of inserting and sealing products into flexible packaging, such as bags or pouches. In addition to this primary function, they can also be used to vacuum seal or add insulating air.

BAGGERS

Available in semi-automatic and automatic models, bagging systems can be configured to suit varying product and production demands of omni-channel retail fulfillment, food packing, medical and healthcare supply distribution, industrial manufacturing and wholesale.

FOOD PACKAGING EQUIPMENT

At PACKPRO, we offer a variety of tray packaging options for our customers specializing in food manufacturing, food processing and food packing.

TRAY SEALERS

Tray sealers are automated systems used to seal trays with film. These systems find application in food processing operations, wherein the food is sealed into the trays. They are highly versatile and can be modified for use with various product sizes and quantities, including conventional tray sealing, tray lidding or skin vacuum packaging.

TRAY OVERWRAPPING MACHINES

Tray overwrapping machines from Ossid deliver high speeds, tight secure wrapping and sustainable efficiencies in materials. automatically wrap trays in stretch film. Servo driven technology and microprocessors reduce downtime and maintenance. Gripper chain system consistently stretches shrink films to produce tightly wrapped packages.

FORM FILL SEAL MACHINES

Form Fill Seal machines include thermoformer that produce various types of packaging. The horizontal form-fill-seal machines we offer deliver flexible to semi-rigid and rigid packages capable of vacuum, modified atmosphere packaging (MAP) and much more. Designed and manufactured in the USA, these machines can handle a broad range of web widths and speeds, providing efficient and consistent output.

With PACKPRO’s Full System approach you can be confident that all your packaging equipment, materials and equipment service requirements will be looked after by our highly-skilled packaging specialists and engineering technicians. Delivering increased productivity, consistent performance and maximized uptime for your packaging operations is our priority.

Our Partners

Offering you exceptional innovative packaging materials and equipment from industry leaders.