In the world of shipping and logistics, ensuring the safety of your packages is critical. One element that often goes unnoticed is the type of tape used to seal your packages. Selecting the right packaging tape not only secures your goods but also impacts your overall efficiency and sustainability. In this guide, we will explore various types of packaging tapes, their applications, and considerations for making an informed choice.

Choosing the Right Tape

When it comes to packaging, not all tapes are created equal. Several factors come into play when deciding on the best tape for your needs:

- Strength: Depending on the weight and type of your package, you’ll need a tape that can withstand the load without breaking. Heavier or bulkier items typically require stronger tapes to ensure they remain securely sealed during transit.The strength of your box also comes into play here—a corrugated box with a double wall is a strong choice to compliment the right tape.

- Durability: The tape should be able to endure various handling processes and environmental conditions. This includes resistance to temperature fluctuations, moisture, and potential rough handling during shipping.

- Appearance: The visual aspect of the tape can affect your brand’s image, especially for consumer-facing packages. Branded tapes can enhance the unboxing experience and reinforce your branding. When the correct tape is selected, you should be able to achieve one strip of tape on the top and bottom of the box.

Two of the most common types of packaging tapes are Pressure-Sensitive Tape (PST) and Water-Activated Tape (WAT).

Pressure-Sensitive Tape (PST)

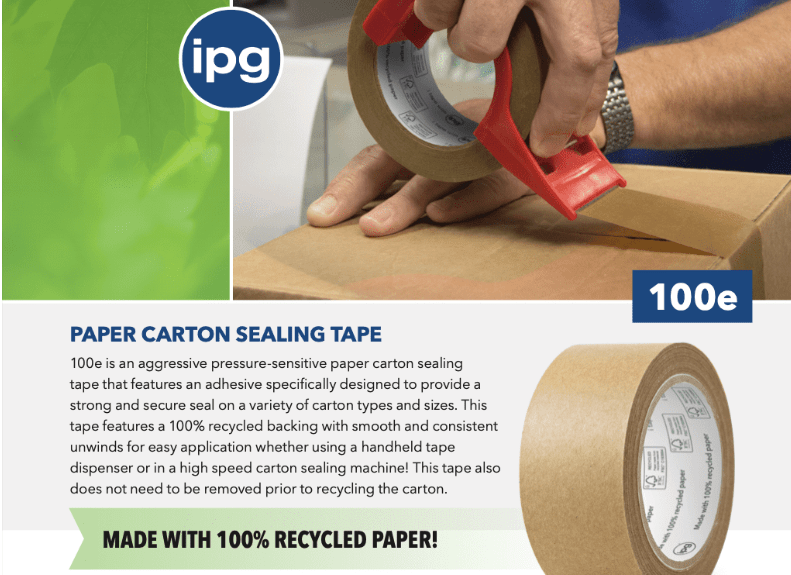

Pressure-Sensitive Tape is a versatile option made by applying a dry adhesive onto a thin plastic film, both petroleum-based substances. PST is easy to use, simply requiring pressure to adhere to surfaces. It is very popular thanks to its convenience and immediate bonding properties. This type of tape is ideal for light to medium-weight packages, and is commonly used in industrial, e-commerce, food packaging, and floral.

Water-Activated Tape (WAT)

Water-Activated Tape, also known as gummed tape, is made of white or natural paper and contains a starch-based adhesive. WAT forms a strong bond when activated with water, creating a secure seal that is ideal for heavy-duty packaging. It is also tamper-evident, providing an additional layer of security. Unlike PST, WAT penetrates the fibers of the carton, creating a stronger bond that is resistant to temperature and humidity changes, making it perfect for long-distance and international shipping.

Packaging Tape Application Options

Packaging tapes can be applied using various methods, each offering different levels of efficiency and cost savings.

- Hand Application: This method is straightforward, and suitable for low-volume operations. But it can be time-consuming and less consistent. Hand application is perfect for smaller businesses or occasional use where investing in additional equipment may not be necessary. However, the variability in tension and sealing quality can lead to varying results, potentially compromising package integrity.

- Dispenser Application: Using a tape dispenser improves efficiency and consistency compared to hand application. It also reduces waste and speeds up the packaging process. Tape dispensers are particularly useful in medium-volume operations where increased speed and reduced tape waste can significantly improve productivity. They ensure a uniform application of tape, reducing the likelihood of tape failure during transit.

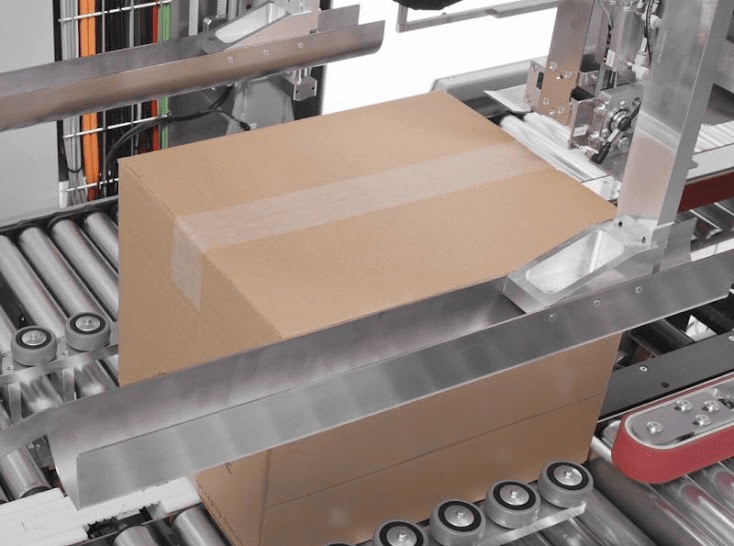

- Machine Application:

Ideal for high-volume operations, machine application maximizes efficiency and accuracy. The initial investment in machinery is offset by long-term cost savings and improved productivity. Machines can handle a wide range of box sizes and provide a secure seal, reducing the risk of packages opening during transport. Additionally, machine application can significantly reduce labor costs and increase throughput, making it a valuable investment for large-scale operations.

Ideal for high-volume operations, machine application maximizes efficiency and accuracy. The initial investment in machinery is offset by long-term cost savings and improved productivity. Machines can handle a wide range of box sizes and provide a secure seal, reducing the risk of packages opening during transport. Additionally, machine application can significantly reduce labor costs and increase throughput, making it a valuable investment for large-scale operations.

Packaging Tape Environmental Considerations

Sustainability is an increasingly important factor in all packaging choices, and tapes are no exception. Today’s market now offers several environmentally-conscious tape options, catering to eco-friendly practices.

- Recycled Plastic Tapes: By reusing plastic, these tapes reduce the reliance on new petroleum-based resources. They provide the same strength and durability as conventional plastic tapes but with a reduced environmental footprint. By choosing recycled plastic tapes, businesses can contribute to the circular economy and show their eco-friendly brand values.

- Recycled Paper Tapes: Comprising recycled paper, these tapes provide a biodegradable option, minimizing the environmental impact. These tapes are not only sustainable but also offer a natural, rustic appearance that can enhance the unboxing experience. Recycled paper tapes break down more easily in the environment, reducing the long-term impact of packaging waste.

Get the Expert Guidance You Need

Choosing the right packaging tape is crucial for securing your packages, optimizing your packaging process, and supporting sustainability efforts. Whether you opt for the convenience of Pressure-Sensitive Tape, the robustness of Water-Activated Tape, or sustainable alternatives, making an informed decision is essential.

Don’t navigate the decision alone—book a consultation with the expert team at PACKPRO. We are here to help you find the perfect packaging solution for your business requirements.