Manufacturers, food processors, and ecommerce retailers of all sizes are relying more on automation to assist them with their packaging process. Some may have implemented automation systems out of necessity during the pandemic, while others had it in their growth plan all along.

Automation in packaging encompasses a wide range of systems designed to optimize and streamline packaging processes. These systems can be tailored to suit the specific needs of a business, offering flexibility and scalability to adapt to changing market demands.

In this article, we’ll unwrap some of the latest trends in packaging automation that are reshaping the industry.

1. Robotics and Collaborative Robots (Cobots)

Packaging automation significantly increases production output compared to manual processes. Collaborative robots, or “cobots,” are designed to work alongside human operators, streamlining manual tasks and increasing throughput.

Packaging automation significantly increases production output compared to manual processes. Collaborative robots, or “cobots,” are designed to work alongside human operators, streamlining manual tasks and increasing throughput.

Automation systems operate continuously without downtime due to fatigue or breaks. This uninterrupted flow in conjunction with a faster pace of throughput helps companies achieve their productivity goals quicker. From pick-and-place operations to assembly tasks, cobots enhance accuracy, reduce labour costs, and ensure consistent quality. This boost in productivity translates to better order fulfillment, and ultimately an increase in revenue.

2. Smart Packaging Lines

Smart packaging lines leverage the power of the Internet of Things (IoT) to create interconnected and data-driven operations. Sensors embedded in machinery collect real-time data, providing insights into performance, efficiency, and maintenance needs. This data-driven approach enables predictive maintenance, minimizes downtime, and optimizes overall equipment effectiveness (OEE).

3. Vision Inspection Systems

Vision inspection systems use advanced cameras and image processing to identify defects, inconsistencies, and errors in real time. Designed to add precision to the packaging process, consistency and standardization are improved. Integrating these systems can help inspect for accuracy on labels, packaging materials, and even the contents of packages.

By catching defects early in the process, you can prevent costly rework and maintain brand reputation. For example, automation can help determine the right amount of product being funneled into a package, if a package is over or underweight, or pause the line if something goes awry.

One of the applications our team worked on was a project that used a laser scanner with an integrated camera / vision for a safety barrier in a large distribution centre, built specially for their pallet inverter equipment.

4. Automated Palletizing and Depalletizing

Warehousing and distribution rely on efficient palletizing and depalletizing. Automated systems can arrange products on pallets or remove them, minimizing manual handling. This improves safety conditions, resulting in reduced employee injury and higher employee morale.

These systems can be customized to accommodate various product sizes and configurations, ensuring optimal use of space and minimizing transportation costs.

5. Sustainable Packaging Solutions

The consistency and efficiency that comes with automation on a packaging line can have a huge impact on sustainable processes. Sustainable packaging solutions align with the growing demand for eco-friendly practices.

Automated systems improve sustainable efforts because they precisely measure and apply packaging materials, reducing waste, and optimizing material usage. By improving sustainable practices, businesses can reduce their environmental footprint while simultaneously improving operational efficiency.

For example, the innovative new technology in the Robot S7 pallet wrapper ensures the lowest practical consumption of materials by reducing film usage up to 35%-45% and power consumption up to 20%.

6. Machine Learning and AI Integration

Machine learning and artificial intelligence (AI) are being used in packaging to analyze data patterns, predict equipment failures, and optimize processes based on real-time insights. By harnessing the power of AI, packaging lines can adapt to changing conditions, enhance efficiency, and ultimately save time and resources.

7. End-of-Line Automation

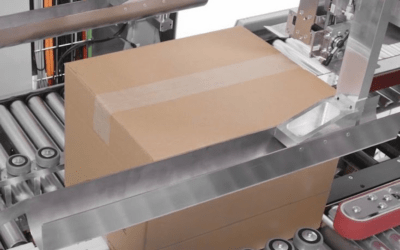

The final stages of packaging—sealing, labeling, pallet wrapping, and quality checks—can also benefit from automation. End-of-line automation systems can handle these tasks efficiently, reducing the risk of errors and ensuring that products are packaged accurately and securely.

Packaging production requires machine operators, quality control specialists, and more, but attracting and retaining skilled labourers is an increasingly competitive task. Managing fluctuating demand and seasonal variations can strain the workforce too, often requiring businesses to scale up or down rapidly.

Automation on packaging lines can help ensure that operations continue despite labour limitations. It can empower employees to focus on quality and productivity instead of repetitive tasks that can easily be taken care of by automation.

Packaging Automation Solutions to Help You Adapt and Succeed

The advantages offered by packaging automation (including improved safety, flexibility, workforce adaptability, and increased production output) are driving its widespread adoption. Packaging automation is not just a trend—it’s a key element in helping businesses navigate evolving packaging challenges in many industries.

Depending on your business and production goals, you may benefit from a fully automated packaging system or custom modular automation tools. Selecting the right automation for your packaging process requires a tailored approach that considers your unique needs.

PACKPRO will help you take the guesswork out of the equipment selection process. Our packaging automation advisors work closely with you to determine your specific requirements before making an equipment recommendation. This personalized approach ensures that your investment in automation solutions align with your objectives, budget, and production volumes.

We offer turnkey solutions that take your project from start to finish. Our engineering team will examine your existing setup and design a custom solution to optimize your process and maximize throughput.

Contact PACKPRO today to see if you qualify for a complimentary assessment of your packaging equipment needs.