Packaging plays a key role in defining both brand identity and consumer satisfaction. It’s one of the initial touchpoints between a brand and its audience, setting the stage for consumer perceptions and experiences. It can also serve as a canvas for creativity with a powerful impact on the customer perception of your brand. Let’s dive into the significance of custom packaging, and how to overcome some challenges that come with it.

Understanding Custom Packaging Materials

Custom packaging materials offer brands a unique opportunity to elevate their image and stand out in competitive markets. Custom packaging enhances both brand perception and product protection, enabling brands to create impactful packaging experiences. For example, choosing mailbags with recycled content can tell a story about your brand values. From premium finishes to sustainable alternatives, there’s an abundance of materials to choose from and give your business an edge.

Although custom packaging typically requires a higher investment upfront, the great returns it delivers when it comes to brand engagement and loyalty make it worthwhile. Plus, there are ways to simplify your approach while still introducing customization.

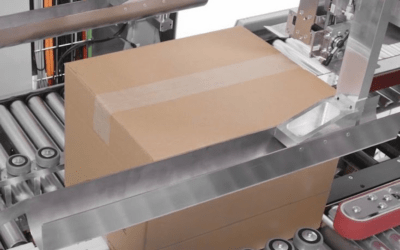

For example, your business may opt for custom packaging tape on plain boxes to start.

Quality tape is not only key to ensuring your package arrives safely, it’s also an opportunity to showcase your branding and your sustainability efforts. You can choose from a variety of colours and materials. As demand for the product increases, you might invest in printed boxes and consider using case formers and case erectors to make your entire packaging process more efficient.

The Growing Demand for Sustainable Packaging

Sustainability has become a key consideration for brands seeking to minimize their ecological footprint and achieve their Environmental, Social, and Governance (ESG) goals. By prioritizing sustainability in the packaging materials, your brand can demonstrate a commitment to environmental stewardship and appeal to eco-conscious consumers.

PACKPRO recognizes the importance of sustainable packaging solutions and offers a variety of environmentally-responsible materials to help brands align with their sustainability goals. From recyclable packaging materials to materials with post-consumer recycled content, you can make environmentally conscious choices without compromising on quality or aesthetics.

Significant material and resource savings are achieved when you ensure your packaging equipment is tuned up and optimized for high performance and efficiency. You can rely on PACKPRO Equipment and Automation Team to assist you with that.

Addressing Industry-Specific Packaging Requirements

Custom packaging can also address goals beyond aesthetics, such as food safety concerns or accommodating sharp objects. For example, food-safe packaging requires materials that are non-toxic, food-grade, and resistant to moisture and grease. Custom packaging allows businesses to select materials that meet these criteria precisely, ensuring compliance with food safety standards. Likewise, packaging for sharp objects can include cushioning or protective inserts to safeguard both the product and the handler. This level of packaging care also builds confidence and trust with customers.

Industries with specific products often have stringent regulatory requirements around packaging. Custom packaging allows businesses to design solutions that comply with these regulations effectively. Whether it’s labeling requirements for allergen information in food packaging or safety warnings for sharp objects, customization ensures adherence to industry standards and regulations, minimizing the risk of non-compliance issues.

Overcoming Challenges with Custom Packaging Automation

Effective packaging solutions go beyond the materials themselves. Custom engineering also plays a crucial role in ensuring that packaging meets the unique requirements of each brand and product as well as other business objectives like throughput. The custom packaging materials you choose must be vetted for performance on your packaging equipment.

Our customers often turn to PACKPRO when they require their existing packaging machines to be upgraded or optimized for the new packaging materials they are implementing. The goal is to ensure that your packaging lines are optimized to pack and protect your products in the most cost-effective way. Here are a few ways you work with a packaging partner to overcome challenges that come with customization:

- Designing custom accessories for your machines to accommodate specific products

- Integrating innovative features for better functionality of your packing lines

- Testing new custom packaging on machines, and fine-tuning if needed

- Customizing your packing line for new products or packaging

Let’s Chat Custom Packaging Solutions

Custom packaging offers brands a powerful means to create meaningful connections with consumers. By curating a mix of materials that reflect the brand ethos, you can appeal to your desired demographic and break away from the competition.

With PACKPRO, you can confidently rely on our expertise to custom engineer solutions that precisely meet (and often exceed!) the unique requirements of your operations.

Connect with us today for a free consultation!