Case forming can become a bottleneck for your fulfillment operations and the reason for costly product damages. Manual case forming often leads to inconsistently formed boxes. First of all, this reduces box strength and compromises box alignment on the pallet. Furthermore, when cases are not vertically aligned, pallet load can lose up to 30% of stacking strength. Finally, weakened load strength means higher risk of product damage in transit. Read more about case forming challenges here.

Benefits of Semi-automatic Case Erectors

As your fulfillment operations grow, automation becomes necessary to support the growth. However, moving from manual case forming straight to fully-automated systems does not always make sense. When volume does not yet warrant full automation, frequent changes of case sizes and pack configurations are required, or quality management includes manual product inspection, semi-automatic case forming may be the most effective and economical choice for your case packing line.

Semi-automatic case erecting machines are designed to deliver multiple benefits for your business with throughput of up to 15 cases per minute:

A semi-automatic case former provides an economical and effective way of increasing case packing productivity.

- Flexible to accommodate changing dynamics of your packing operations:

Easy tool-less case size changes with change points accessible from both operational sides of the machine.

- Built to deliver fast, reliable, efficient packing:

Dynamic flap-folding system actively folds all bottom flaps; formed cases are positioned on a roller deck for easy loading and transfer to case sealer; positive mechanical case hold-down keeps box in place for hands-free loading.

- Ergonomic and user friendly for faster adoption and convenient operation:

On-machine Instructions, user-friendly pictorial guides, color coded labeling for quicker operator training and ease of use.

- Safer with better productivity:

Helps minimize repetitive strain injuries or paper cuts associated with manual carton folding.

As a result, installing a semi-automatic case erecting machine improves packaging productivity and frees up staff for other operations. Moreover, a semi-automatic case former combined with a case sealer provide an economical and effective way of erecting and sealing the cases faster and more securely.

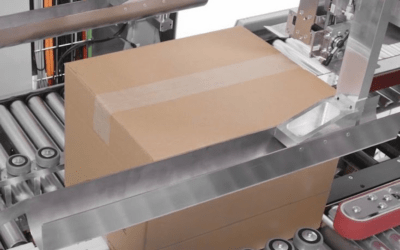

Fully-Automated Case Forming Systems for Higher Throughput

In contrast, if your business demands higher case packing throughput (up to 20-30 cases per minute), we can help you choose a fully-automated case forming system. Wexxar’s superior case erecting systems maximize throughput and reliability of your case packing operations, regardless of corrugated quality. They deliver the highest quality output and maximum up-time.

Why case forming automation is worth it

Automating your case forming process at the right time with the right equipment is sure to deliver increased packaging productivity and operational efficiencies. Perfectly square cases made by a case erector and securely sealed by a case sealer, stack more easily and are stronger. As a result, they are less prone to being damaged during the shipping process. More importantly, the products you are shipping are better protected to arrive in perfect condition, delighting your customers.

Contact us today to see what case forming and sealing solution can help advance your packaging operations.

Yes, I’d like more info on case forming equipment!